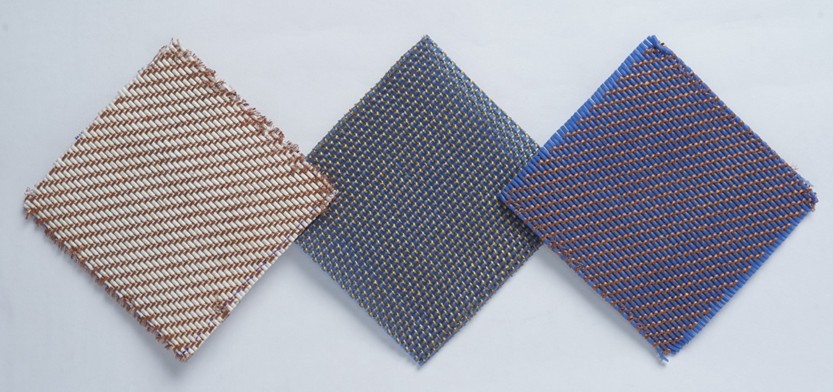

We are manufacturers of Cushion Pads for hot lamination presses. Cushion Pads find extensive application in laminating presses of particle board, plywood & MDF Boards. We have a fully vertically integrated manufacturing facility for cushion pads. Our process starts with sourcing of high quality silicone rubber and copper from established companies. We have our own in house silicone wire extrusion facility, copper and bronze wire bunching, rewinding machine and weaving looms to ensure consistent quality of our Cushion Pads, which are, high temperature, high fatigue and high pressure resistant. It has a good cushioning effect and low compression set. They can endure high temperature continuously and transfer heat and pressure uniformly. Our cushion pads are more resistant to oil turbidity and have a longer service life.

| PAD TYPE | PAD – A | PAD - B |

|---|---|---|

| MATERIALS | COPPER WIRE AND SILICONE WIRE | BRASS WIRE AND SILICONE WIRE |

| THICKNESS | 2.2mm ~ 2.5mm | 2.2mm ~ 2.5mm |

| GSM | 4600-4800 gsm | 3800-4000 gsm |

| WEAVE PATTERN | Twille | Plain |

| TEMPERATURE RESISTANCE | ≤260*C | ≤260*C |

| OPERATING PRESSURE | ≤70kg/cm2 | ≤70kg/cm2 |

| HEAT TRANSFER | Lower | Higher |

| CUSHIONING EFFECT | Higher | Lower |

| RESISTANT LIFE | Higher | Lower |